Because “tightening things” shouldn’t feel like solving a Rubik’s Cube in the dark.

By Samantha Callaghan

1. Know Your Bolts, Know Your Battle Plan

Before you fall in love with shiny tools, figure out what you’re actually tightening.

What’s the job? Pipeline flanges, turbine studs, structural anchors — or the mystery bolts no one admits to installing?

What size, grade, and thread are we talking about?

What torque or preload do the engineers demand this week?

Where are you working — an offshore platform, a cramped corner, or a heatwave in a metal box?

Figure it out before you fire it up — “oops” and 10,000 psi don’t make a good duet

2. ⚔️ Torque vs. Tension — Choose Your Fighter

Step into the arena — two legends, one job site. Who will you pick?

🥊 Torque Tool

Fast. Fierce. A little rough around the edges.

This powerhouse thrives on speed and muscle — perfect when “close enough” still gets the job done.

He’s the brawler of the bolting world: less talk, more twist.

Special Moves:

Lightning-fast torque delivery

Works in almost any arena

Bonus points for brute force and reliability

Weakness:

Not the best at “perfect accuracy” — think street fighter, not surgeon.

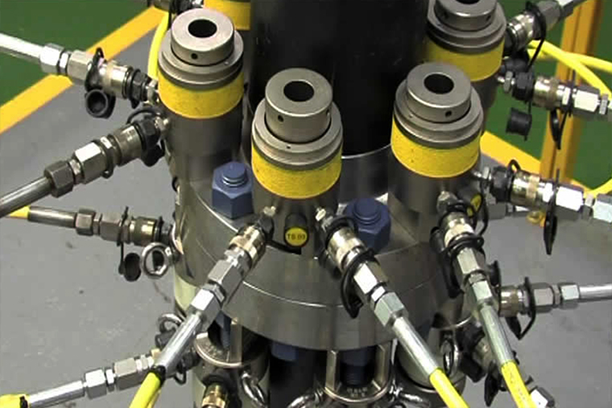

3. ⚔️ Tensioner

Smooth. Precise. The tactician.

This hero doesn’t just tighten — it elevates preload perfection to an art form.

Ideal for high-stakes battles like pressure vessels, turbines, and anything that makes engineers sweat.

Special Moves:

Even, repeatable preload

Zero friction drama

Makes QA departments swoon

Weakness:

Takes a little longer to set up, but worth every second for that flawless finish.

Muscle Matters — Pick the Right Power

Think of it like choosing the right club on the golf course — it’s all about matching your swing to the shot.

Your bolts are the fairway ahead: you need enough power to reach the green, but not so much that you overshoot into the rough.

Biggest bolt = your driver. That’s your baseline — the longest shot, the most force.

Add a little extra muscle (10–20%) for real-world friction and operator “enthusiasm.” It’s your wind adjustment.

But don’t overdo it — no one needs a torque wrench that could launch the ball into orbit when all you needed was a solid mid-range hit.

Choose your gear like a pro picks a club: deliberate, precise, and with just enough power to make it look effortless.

4. Pump It (But Smartly)

Your pump is the unsung hero — do your research and get the right one.

Field jobs: Portable air or battery pumps keep things moving.

Shop setups: Electric or air-driven pumps for speed and endurance.

Just make sure your pump and tool speak the same pressure language (usually around 10,000 psi).

5. Comfort Counts

A good fit isn’t just for jeans; don’t worry we won’t make you turn around like your mom did to find the right fitting jeans.

Does the tool fit where you need it to go?

Can you lift it without needing a chiropractor?

Do the hoses, couplers, and reaction arms actually connect?

Ergonomics might not sound exciting, but your shoulders will thank you later.

6. Vendors: Swipe Right Wisely

Choose a supplier who’s in it for the long haul — not just the first date.

Calibration certificates? ✅

Spare parts that don’t take six months? ✅

Real customer stories and local support? Double ✅

Final Word: Tighten Smarter, Not Harder

Finding the right hydraulic setup isn’t about knowing every spec — it’s about knowing your job, your bolts, and your limits.

Get that right, and every bolt will click into place like you planned it that way all along.

(Bonus points if you look heroic doing it.) 😎

💪 At Northland Air Hydraulics, we’ve got your back.

From narrowing down your exact needs to calibrations, repairs, and everything in between — we’ll walk with you every step of the way.

Because when it comes to hydraulic power, you don’t have to go it alone