By Samantha Callaghan

🏋️ Step 1: So, What’s the Big Deal About Enerpac Cylinders?

Enerpac doesn’t make your average, run-of-the-mill “maybe-it’ll-lift” cylinders. These are the heavy lifters of the hydraulic world — the kind that quietly move bridges, hold up mining equipment, or rescue your 40-ton machinery when gravity gets ambitious.

From compact single-acting cylinders that slip into tight spots to giant high-tonnage beasts that could probably lift your entire shop (and your ego), Enerpac’s got a cylinder for every kind of lift.

📏 Step 2: Start with the Big Three — Stroke, Tonnage & Height

Hydraulic cylinders come in all shapes, sizes, and personalities, but you’ll want to focus on three main traits:

Tonnage: How much it can lift. Enerpac cylinders range from light 5-ton models to 1,000-ton monsters that make forklifts look like toys.

Stroke: How far it lifts. Need a little nudge? Try a short-stroke. Need a big lift? Go for a long-stroke or telescopic model.

Collapsed height: How much space it takes up before extending. Low-profile cylinders are your best friends in tight spaces — they do the heavy lifting without taking up real estate.

Pro tip: Always choose a cylinder with about 20% more capacity than you think you’ll need. (It’s like dessert — better to have extra.)

🧠 Step 3: Pick Your Personality Type — Cylinder Edition

Enerpac’s lineup has more variety than a coffee shop menu. Here’s a quick cheat sheet:

RC-Series (Classic General Purpose):

The workhorse. Reliable, rugged, and ready for almost anything. Perfect for lifting, pressing, or straightening tasks.RSM & RCS-Series (Low Profile):

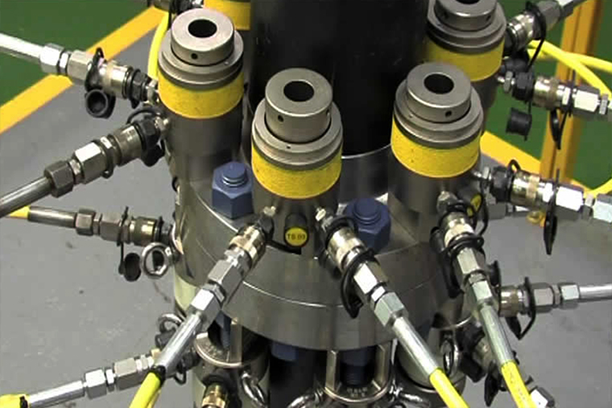

Short and strong — for when space is tighter than your lunch break. Ideal for industrial maintenance and confined lifts.RR-Series (Double-Acting Power):

Push and pull with fluid force. Great for precision jobs, tensioning, or when gravity just isn’t doing enough.CLS & CLP-Series (High Tonnage):

The heavy hitters — built for bridge jacking, shipbuilding, and “we’re gonna need a bigger pump” moments.RT-Series (Telescopic):

When you need a long reach without a tall setup. Perfect for lifts that need more travel but less space.RSM-Series (Flat Jacks):

Pancake-shaped powerhouses — thin but mighty. Great for lifting heavy loads just a few inches.

🧯 Step 4: Single-Acting vs. Double-Acting — It’s a Commitment Thing

Enerpac makes both, and which one you need depends on your relationship with gravity:

Single-Acting: Lifts with hydraulic pressure, returns with gravity or a spring. Simple, compact, and perfect for most maintenance and repair jobs.

Double-Acting: Lifts and retracts using hydraulic power — faster, more control, and ideal when you can’t rely on gravity (or patience).

🌡️ Step 5: Match the Cylinder to the Job

Maintenance & repair work? RC or RCS series — easy to use, simple to carry, and strong as an ox.

Precision positioning or pulling? RR or RD series — double-acting precision at your fingertips.

Heavy construction or bridge lifting? CLS or HCG series — maximum tonnage, maximum confidence.

Tight spaces? RSM series — flat, fast, and fearless.

🔧 Step 6: Don’t Forget the Accessories

A cylinder’s only as good as what’s connected to it. Pair it with:

The right pump (air, hand, or electric — Enerpac’s got them all)

Proper hoses and couplers rated for your pressure

Load return valves and pressure gauges for safe, controlled lifting

Because safety isn’t optional — and a little extra prep today means no hydraulic drama tomorrow.

🧽 Step 7: Maintenance — The Secret to Cylinder Longevity

Even Enerpac cylinders appreciate a little TLC. Regular cleaning, proper oil, and keeping those seals in check will make your cylinder last years longer.

And if that sounds like a lot, don’t worry — we can help with that too. Our team can assist with setup, troubleshooting, and regular maintenance to keep your system running like the day it came out of the box.

🎉 Final Thought

Choosing the right Enerpac hydraulic cylinder isn’t guesswork — it’s about matching strength, stroke, and style to your lifting needs.

Whether you’re raising heavy equipment, pressing parts into place, or straightening steel, there’s an Enerpac cylinder made for the job — and we’re here to help you find it.

From helping you pick the perfect model to keeping it maintained for years of flawless lifts, we’ll make sure your cylinder keeps doing what it does best:

lifting heavy, working smart, and staying smooth under pressure.